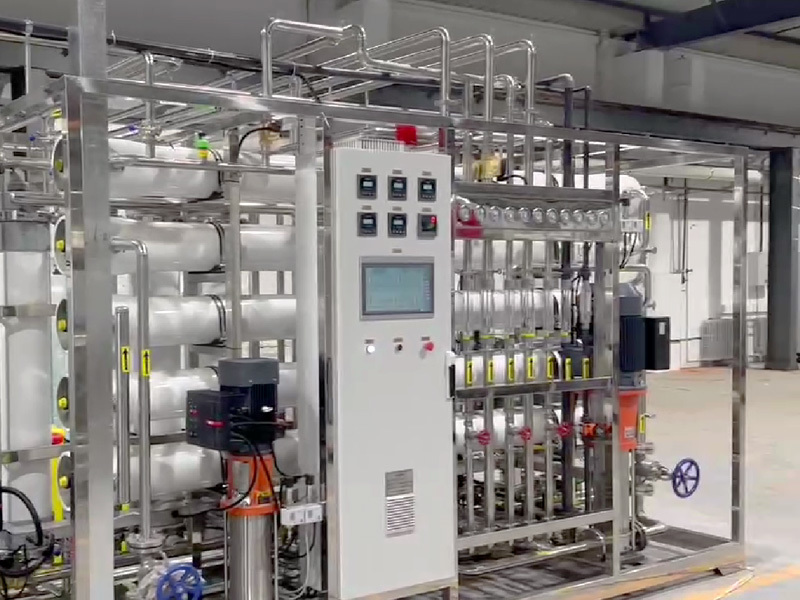

XMUF series ultrafiltration system

Telephone:86-22-84940334

E-mail:aaa_668@126.com

Keyword:

Classification:

Product Introduction

Overview

Membrane separation phenomena are prevalent in natural evolution and the metabolism of organisms. After half a century of development, membrane separation technology has transitioned from laboratory to large-scale industrial applications, playing a crucial role in industrial production. Ultrafiltration membrane separation technology, as one of the six major high-tech fields of this century, has been rapidly applied worldwide due to its advantages of operating at normal temperature and low pressure without phase change and low energy consumption. Its applications span drinking water purification, beverages and food, pharmaceuticals and medicine, and wastewater reuse.

Ultrafiltration Membrane Structure and Working Principle

Ultrafiltration membranes typically consist of a skin layer and a support layer. The skin layer is located on the membrane surface and has a tightly packed structure of polymer globules formed by liquid-liquid phase separation. The size of these globules is approximately 30-200 nm, gradually increasing in the thickness direction of the skin layer, which generally has a thickness of 2-3 μm; the support layer is divided into two types: sponge-like and finger-like structures. The membrane thickness is mainly determined by the support layer. As shown in Figure 1: The ultrafiltration separation process is a sieve-pore separation process. Under a certain pressure, when a mixed solution containing large and small molecules flows through the supported membrane surface, the solvent and small molecule solutes (such as inorganic salts) will pass through the membrane, while the macromolecular solutes are retained by the membrane as a concentrate due to adsorption (adsorbed on the surface and pores of the filter membrane), blocking (retained in the pores), and sieving (mechanically retained on the surface of the filter membrane).

Ultrafiltration Membrane Product Classification

With technological advancements and widespread applications, the types of ultrafiltration membranes are increasing. Different classification methods yield different results. If classified according to different types of ultrafiltration membrane modules on the market, they can be simply divided into the following categories: hollow fiber type (including inner pressure type and outer pressure type), plate type, tubular type, and spiral wound type.

Advantages of XMUF Ultrafiltration

(1) Separation is performed at normal temperature and low pressure, resulting in low energy consumption and thus low equipment operating costs;

(2) The equipment is small in size and simple in structure, resulting in low investment costs;

(3) The ultrafiltration separation process is simply pressurizing and transporting liquid; the process flow is simple and easy to operate.

(4) Ultrafiltration membranes are made of high-polymer materials, forming a uniform continuous body. It is a purely physical filtration method, and no impurities will detach during operation, ensuring the purity of the ultrafiltrate.

Honor

Product Consulting

If you want to ask questions, we will send experts to contact you within one working day. Please leave your contact information.

Contact Us

Telephone:86-22-84940334

Mobile:86-13802196330

E-mail:aaa_668@126.com

Address: Tianjin Lixing Boyu Metal Products Co., Ltd., No.38 Jixian Road, Jinnan District, Tianjin