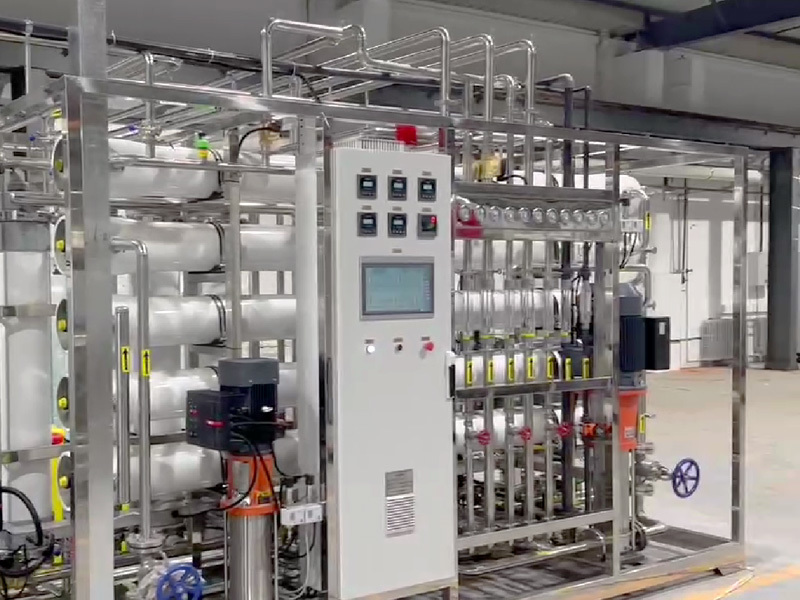

XMEDI desalination system

Telephone:86-22-84940334

E-mail:aaa_668@126.com

Keyword:

Classification:

Product Introduction

Overview

Electrodeionization (EDI), formerly known as continuous deionization (CDI), is an environmentally friendly water treatment technology that removes ions from water using ion exchange resin membranes and ion exchange resins under an electric field without the need for regenerants. It combines the advantages of electrodialysis and ion exchange mixed bed technologies to achieve deep desalination.

An EDI device essentially performs electrodialysis desalination with the addition of anion and cation exchange membranes within the electrodialysis unit. Even then, approximately 3% of salts remain in the freshwater chamber. Since 97% of the ions are migrated, the conductivity of the water decreases. To further increase the desalination rate, energy consumption would significantly increase. Filling the freshwater chamber with anion and cation exchange resins creates a mixed bed that continues to exchange the remaining salts. Simultaneously, the addition of ion exchange resins increases the conductivity of the freshwater chamber, preventing an increase in water production costs. Furthermore, the greatest advantage of EDI technology is its use of electrodialysis polarization and hydrolysis to continuously regenerate the anion and cation exchange resins with hydroxide and hydrogen ions, creating a dynamic process of continuous deionization and continuous electroregeneration.

The main advantage of EDI technology is its ability to produce near-theoretically pure desalinated water with a conductivity of ≤0.06 μS/cm, without the use of chemical regenerants and without waste liquid discharge, thus achieving pollution-free pure water production. Because EDI produces high-purity water that meets or exceeds the level of ion exchange mixed beds without requiring acid-base regeneration, and because it uses electricity for desalination to achieve a water quality far beyond that of electrodialysis, EDI technology is particularly advantageous in today's environmentally conscious world. Using reverse osmosis (RO) to treat high-salinity water followed by EDI to continuously produce ultrapure water further highlights the advantages of EDI technology.

EDI Working Principle

EDI is a technology that combines ion exchange mixed beds and electrodialysis, leveraging the advantages of both while overcoming their respective drawbacks. The biggest difference between EDI and traditional ion exchange technology lies in the resin regeneration method. EDI uses direct current electricity for continuous regeneration, eliminating the need for chemical reagents. An EDI unit consists of a freshwater chamber and a concentrate chamber (some products do not have a concentrate chamber). The freshwater chamber is filled with mixed ion exchange resin, hence its width is larger than the concentrate chamber, removing ions from the feed water. Selective anion and cation exchange membranes are placed between the freshwater and concentrate chambers. Under the influence of electrodes at both ends, cations and anions in the freshwater chamber continuously migrate directionally, passing through the anion and cation exchange membranes into the concentrate chamber. Water is decomposed into H+ and OH- by direct current electricity, keeping the mixed ion exchange resin in the freshwater chamber constantly regenerated and maintaining its exchange capacity. The concentrate in the concentrate chamber is continuously discharged. Each water production unit in the EDI device consists of a set of resins, ion exchange membranes, and spacers. Multiple water production units are connected in parallel to form a complete EDI device. While powered, EDI continuously produces pure water without requiring acid-base regeneration of the internal resin.

Advantages of XMEDI

(1) The effluent water quality has optimal stability;

(2) It can continuously produce ultrapure water that meets user requirements;

(3) Modular production, the entire system is fully automated;

(4) No acid-base regeneration is required, and no wastewater is discharged;

(5) Simple operation and low labor intensity;

(6) No downtime due to regeneration;

(7) No regeneration equipment or chemical reagent storage and transportation is required;

(8) Compact equipment structure and small footprint; (9) Low operating and maintenance costs.

Honor

Product Consulting

If you want to ask questions, we will send experts to contact you within one working day. Please leave your contact information.

Contact Us

Telephone:86-22-84940334

Mobile:86-13802196330

E-mail:aaa_668@126.com

Address: Tianjin Lixing Boyu Metal Products Co., Ltd., No.38 Jixian Road, Jinnan District, Tianjin